1 / 3

1 / 3Camera-based pick and place

Hardware Price:

DOF

3

Project costs

before invest

£

Characteristic

quiet

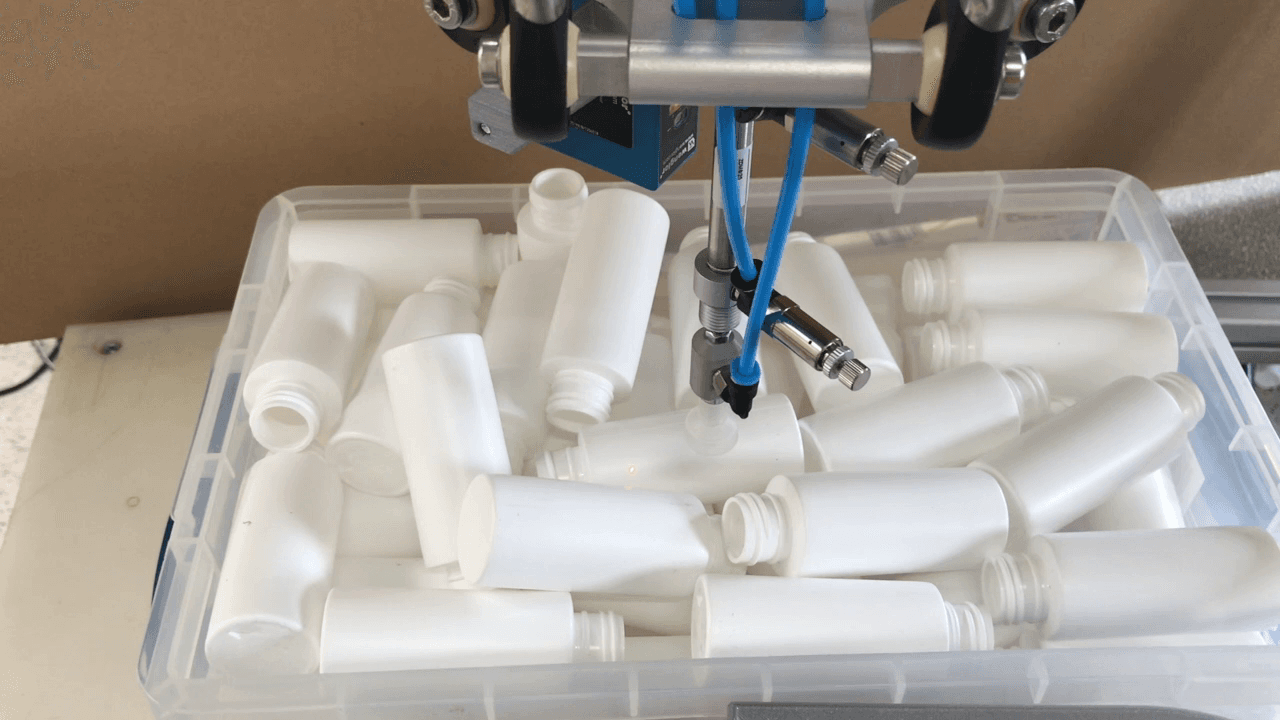

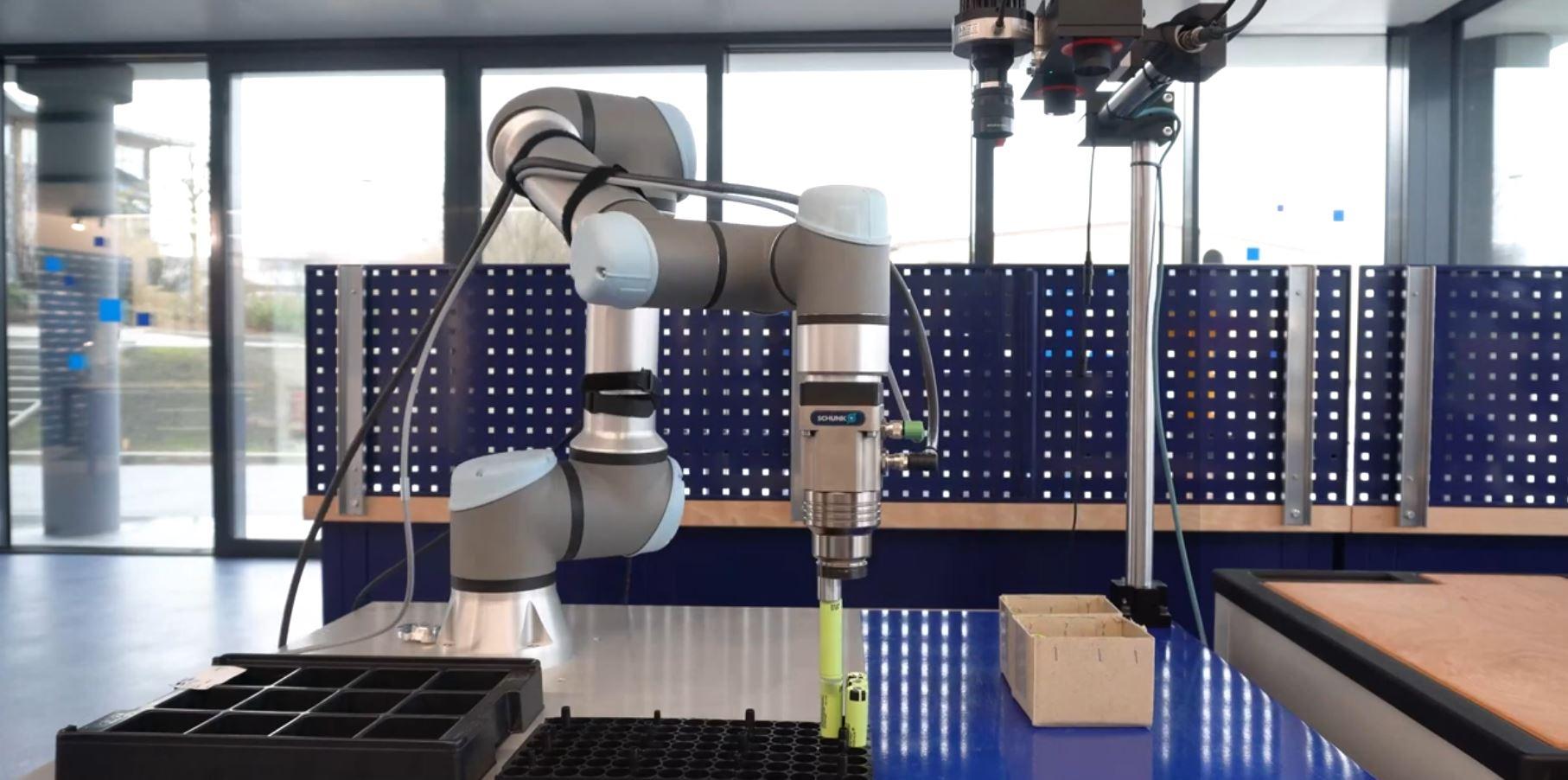

In this application, a pick and place task was realised with a spatial gantry in combination with a camera system. The camera makes the application more intelligent, as the components to be gripped no longer always have to be in the same position, but are identified independently by the robot. This makes the whole system more fail-safe and flexible.

This smart solution both relieves employees and reduces costs, as the robot can work in 3-shift operation. Thus, the investment pays for itself within a few months.

3 Components